DIE CUTTING SOLUTION

Unmatched Quality

DIE CUTTING SOLUTION

Die cutting solutions revolutionize production processes by precision cutting materials like paper, cardboard, plastics, and metals into intricate shapes and designs. From packaging to automotive components, these versatile solutions ensure efficiency and accuracy in manufacturing. With advanced technology and customizable options, die cutting solutions streamline production, delivering high-quality results for a myriad of industries worldwide.

LASER DIE MAKING

CREASING MATRIX

EVA FOAM

INJECTION RUBBER

STEEL SHIM TAPE

PAPER PATCHING TAPE

CUTTING RULE

CREASING RULE

DIE PUNCH BIT

PAPER DRILL BIT

NICK GRINDER

JIGGING SAW BLADES

Series

Plastic based Creasing Matrix(white/yellow/orange)

Type

Standard/Narrow/Off-center/Double

Material

PVC base with plastic shoulder

Punching Time

10,000-30,000 times

Application

Developed for small and medium print runs

Packing

70cm/pc,50pcs/box, 10boxes/carton

Storage Period

2 years

Notes

Matrix in rolls is available upon demands

How to use

- Measure the length of the creasing rule

- Mark the measurement and cut the matrix

- Mount the cutting piece into the creasing rule with locator

- Remove all of the backing tapes

- Transfer the matrix to the die cutting steel plate

- Remove all of the locators

- Miter the sharp angle

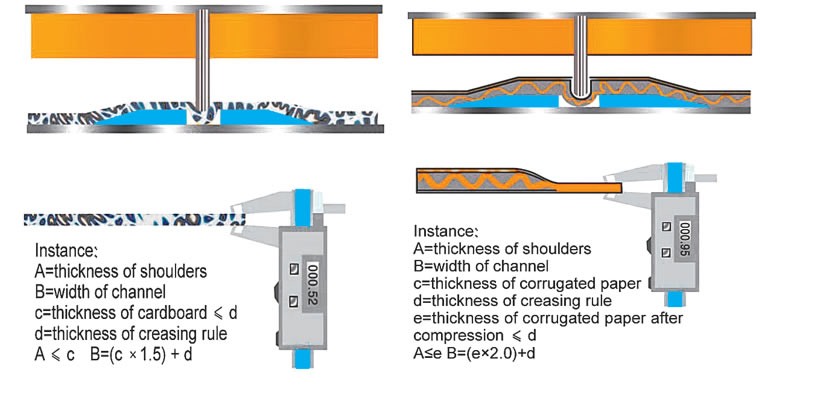

calculation formula

SPECIMENS

Specimens in die cutting often encompass a range of raw materials such as paper, cardboard, plastics, textiles, leather, rubber, foam, and even metals. Each material has distinct properties that influence the die cutting process, including thickness, density, elasticity, and tensile strength.

- TMB 0.3x0.8 mm (12mm)

- TMB 0.3x1.2 mm (12mm)

- TMB 0.4x0.8 mm (12mm)

- TMB 0.4x1.2 mm (12mm)

- TMB 0.4x1.3 mm (12mm)

- TMB 0.4x1.5 mm (12mm)

- TMB 0.5x1.5 mm (12mm)

- TMB 0.5x1.7 mm (12mm)

- TMB 0.6x2.5 mm (12mm)

- TMB 0.8x2.5 mm (12mm)

- TMB 0.8x2.7 mm (12mm)

- TMB 0.8x3.0 mm (12mm)

- TMB 0.8x3.5 mm (12mm)

- TMB 1.0x3.0mm (12mm)

- TMB 1.0x3.2 mm (12mm)

-

Green High Elasticity Injection Rubber

60° Green High flasticity-10x300x380mm 2018x -

White High Elasticity-10x300x380mm x 20/Box

40° White High Elasticity-10x300x380mm x 20/Box

Features

- World's most advanced creasing matrix made from plastic, pressboard and fibre and resin for various die cutting jobs

- Accurate locator- ensures perfect registration

- Low profile chamfer-board flows freely over the matrix, board marking is reduced

- Finger lift adhesive tape-backing paper easily and quickly removed

- New and strong adhesive removes cleanly from the plate after use, will not move about during die cutting jobs

- Special sizes available to suit all board types, off-centers and multi-crease for close creasing rule

- It is extremely durable and accurate and provides benefits in time and cost